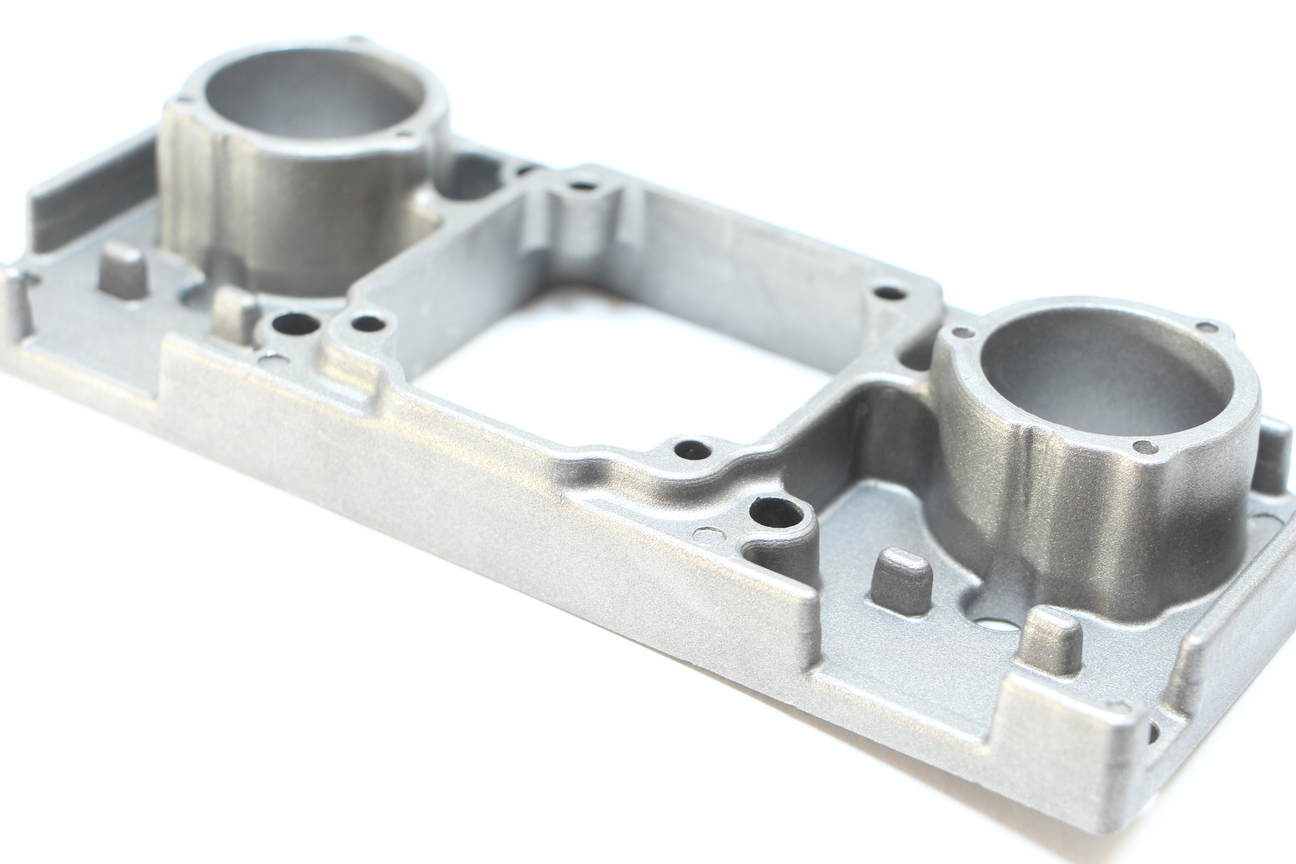

Vibratory machining

In case of vibratory finishing, we use abrasive media of varied shapes, sizes, and chemical compositions to achieve the desired surface condition of the castings.

Blasting

Depending on the casting’s size, shape, and weight, we offer two kinds of shot blasting — barrel or suspended. It is possible to use abrasives of different sizes, e.g., CR30 or CR40.