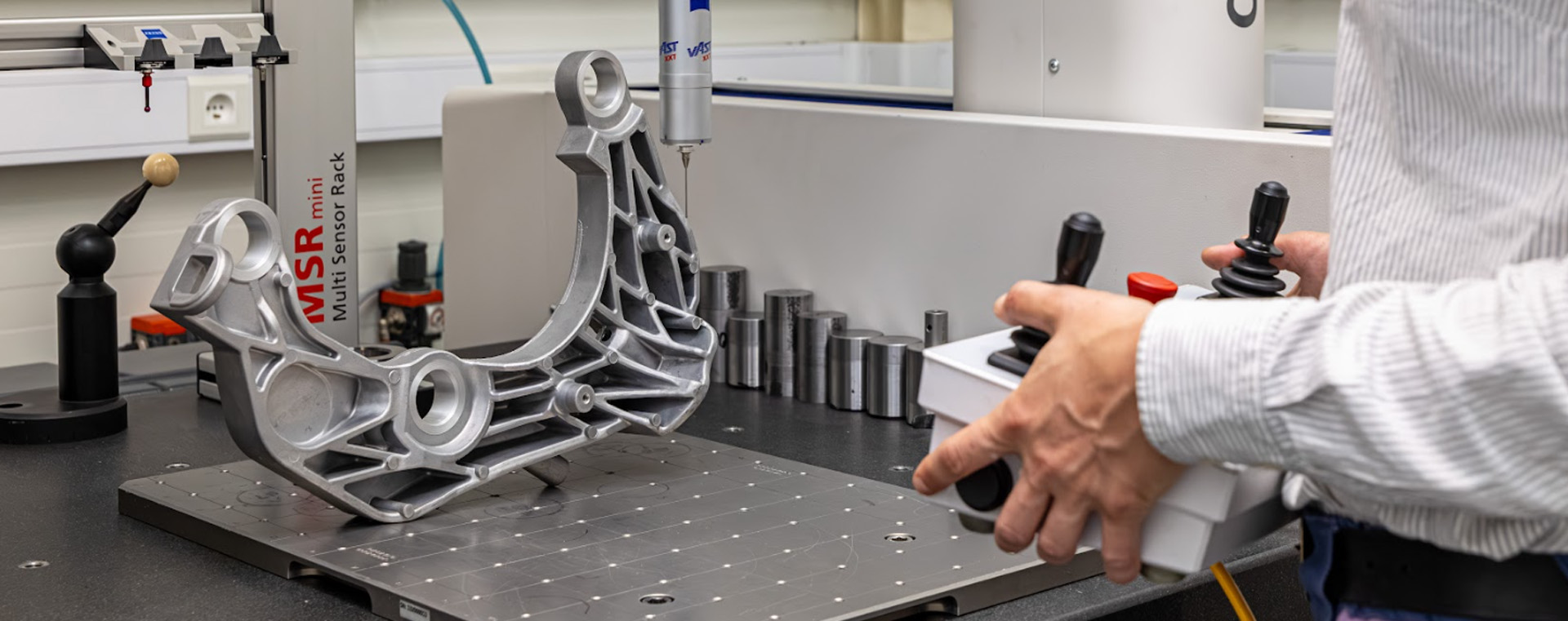

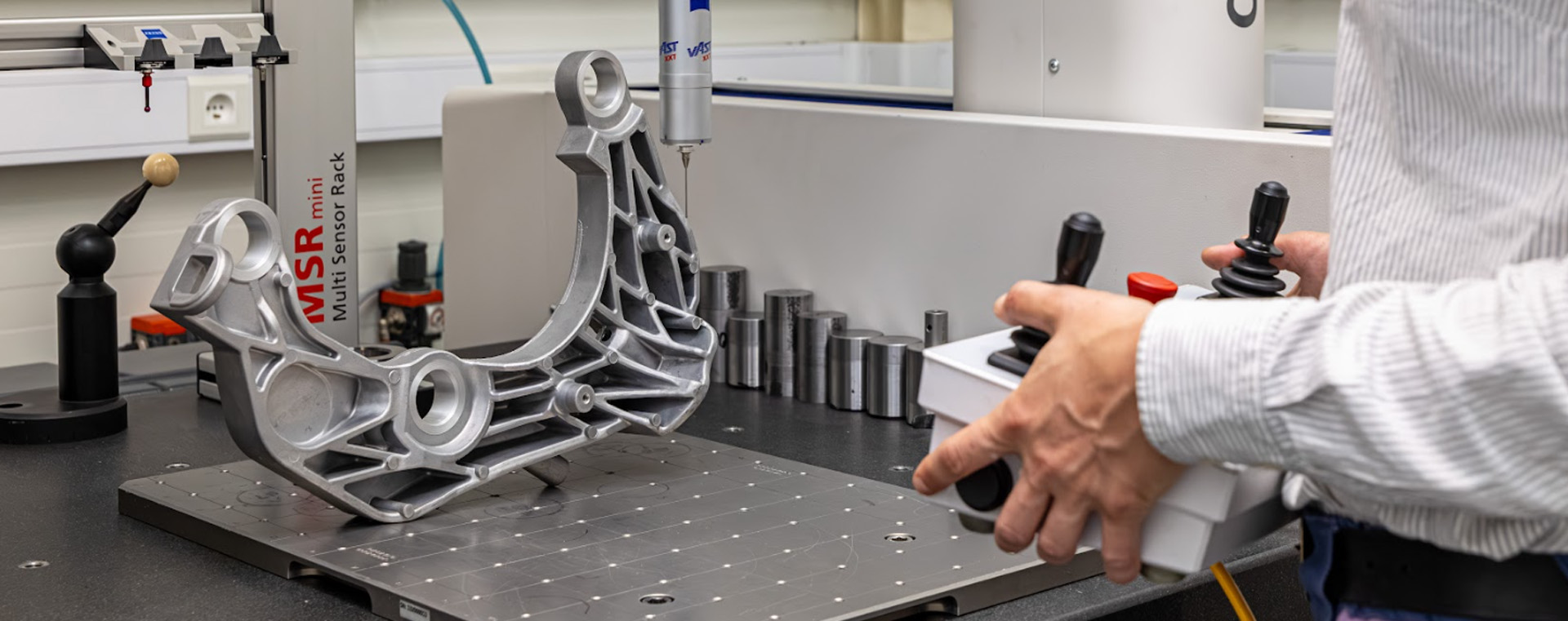

Adaptation of a customer-supplied mould

If the use of a customer-supplied mould is required, we commission the tool shop to adapt these tools to fit our machines and foundry standards.

At the design stage, we provide support in optimizing the design to suit high-pressure die casting technology. This ensures proper filling of the mold cavity with molten metal and facilitates the efficient removal of the finished casting.

If the use of a customer-supplied mould is required, we commission the tool shop to adapt these tools to fit our machines and foundry standards.

In case of high-pressure die casting, the mould is, essentially , the “key” to success.

A correctly designed mould enables achieving the required structural and surface quality of the castings, as well as the intended efficiency of the casting process. Equally important are the precision and quality of the mold itself, together with the materials used in its construction — all of which impact the durability and reliability of the tooling.

Do you have questions about molds, manufacturing or machining? Contact us – we will be happy to explain everything.

Pon. – Pt. : 7:00 – 16:00

For us, project optimization is a collaborative process with the client aimed at finding a compromise between their vision concerning the shape and design of the part and the constraints or requirements imposed by the die casting technology.

In most cases, this service is offered free of charge, if it results in project execution.

Yes, we do offer casting services using customer-supplied moulds, although not unconditionally. Each tool must undergo our verification process to confirm that it has been manufactured in accordance with die casting standards and that its condition allows for achieving the expected process efficiency.

The adaptation cost of a customer-supplied mold can be calculated after having been inspected by our engineers.

Similar to mold adaptation, the cost of test casting cannot be assessed in advance. Customer-supplied moulds get to us in various technical conditions, and often their activation takes considerable time. Other times, everything proceeds smoothly without unexpected issues.

In the case of implementing a new mould manufactured by Metalform sp. z o.o., trial castings are free of charge.