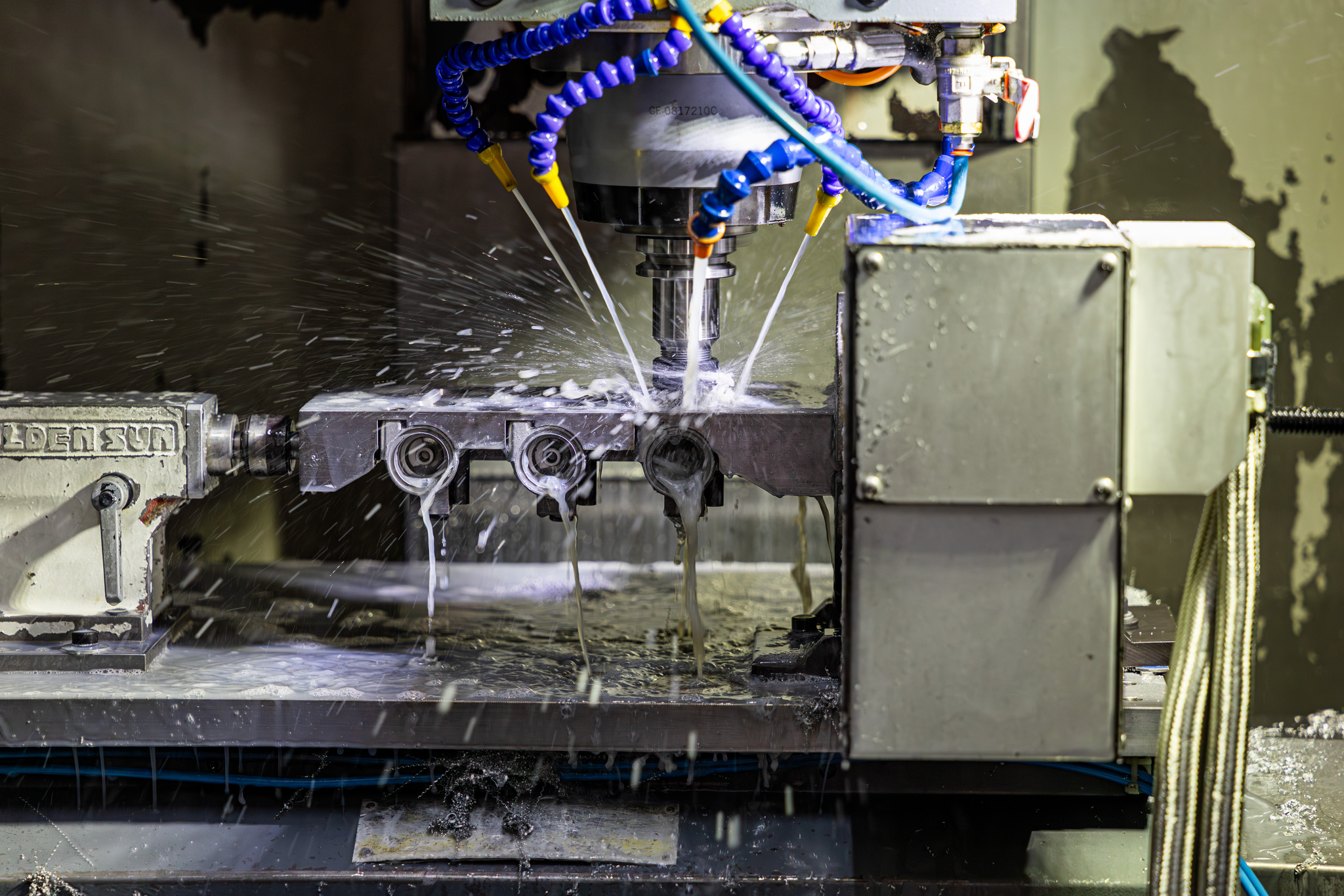

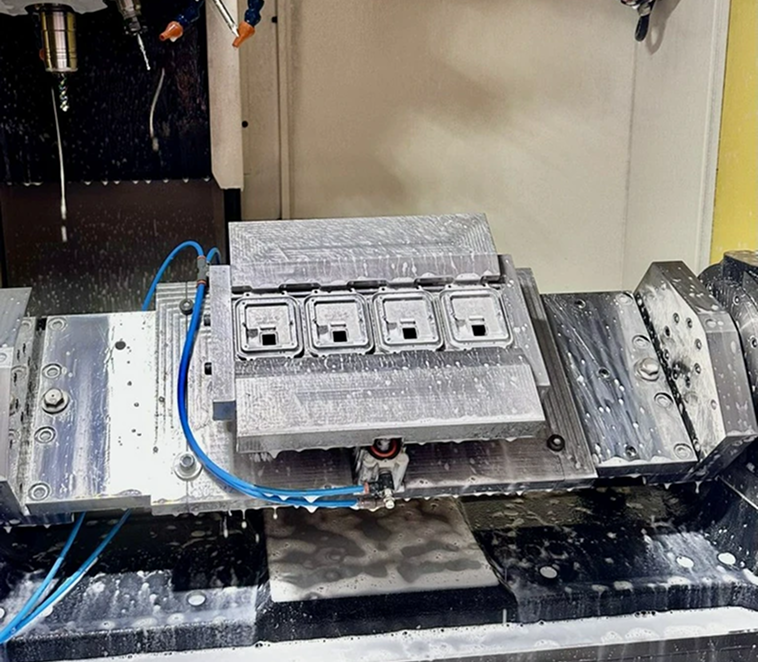

CNC machining

– precision and repeatability

We undertake this kind of machining operations using 3- and 4-axis machining centers.

After CNC processing, the parts are transferred to an ultrasonic cleaning system to remove any residues of process fluids from their surfaces.

What we offer:

Milling – performed on 3- and 4-axis CNC machining centers, allows precise shaping of workpiece surfaces, creating nests, grooves, pockets and other geometric structures.

Drilling – we realize drilling of technological, assembly and threaded holes with high positioning accuracy.

Threading – mechanical cutting of internal and external threads according to customer requirements (various standards, lengths and thread diameters).