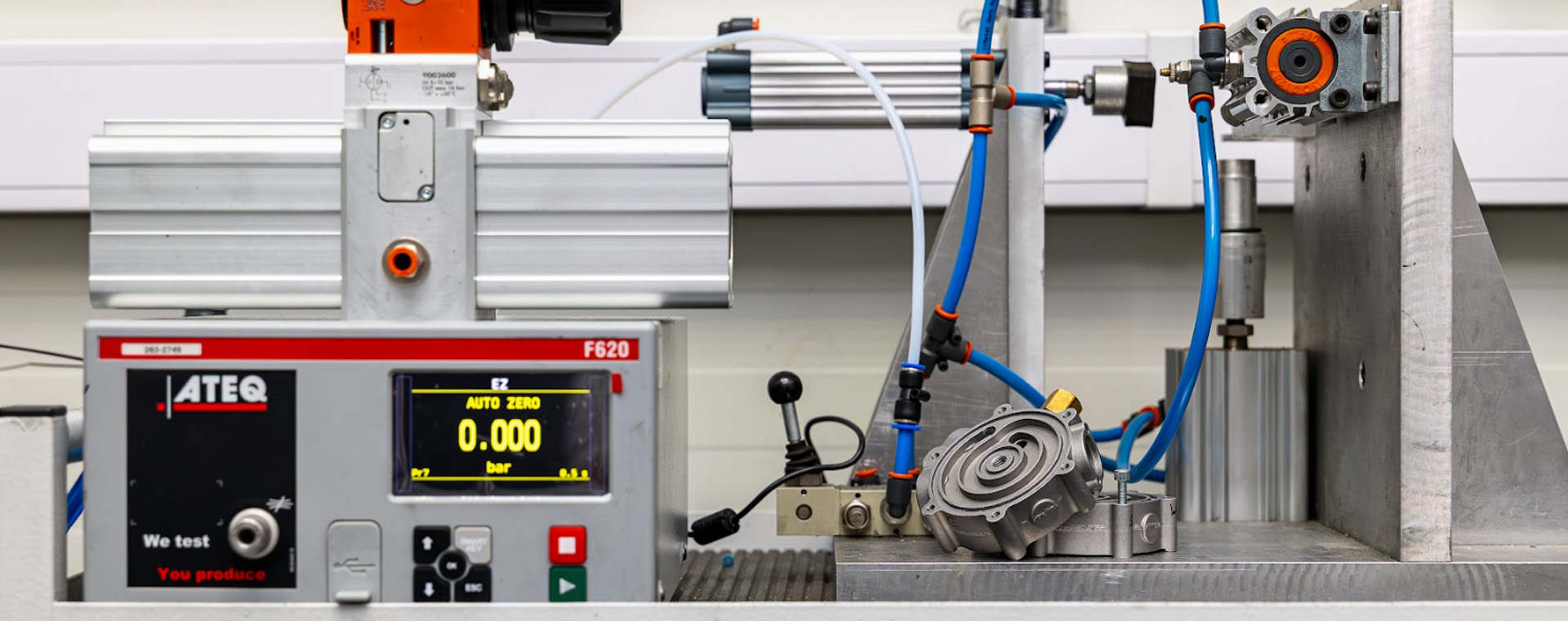

Casting sealing and leak testing

We can provide additional sealing for parts with increased sealing requirements. Leak testing can be performed using two methods. The pressure drop method in a control system or the immersion method in a testing medium, e.g., water.