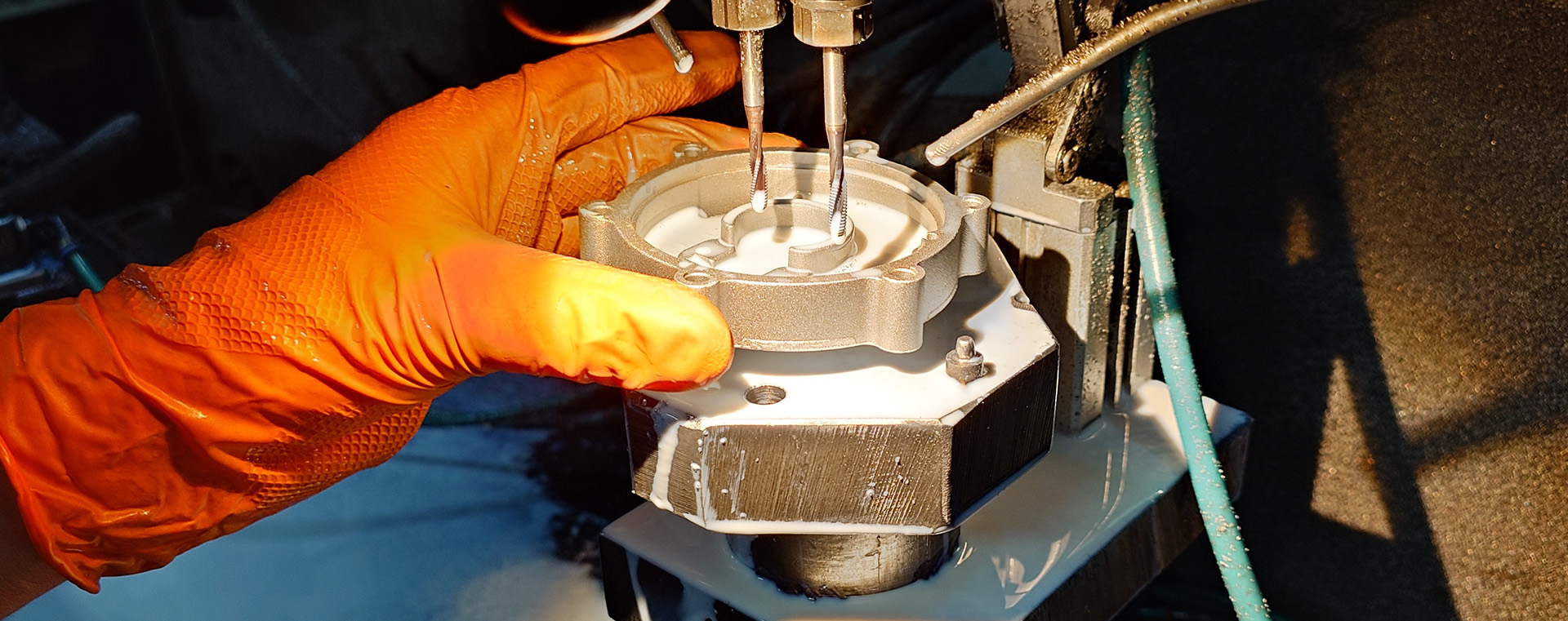

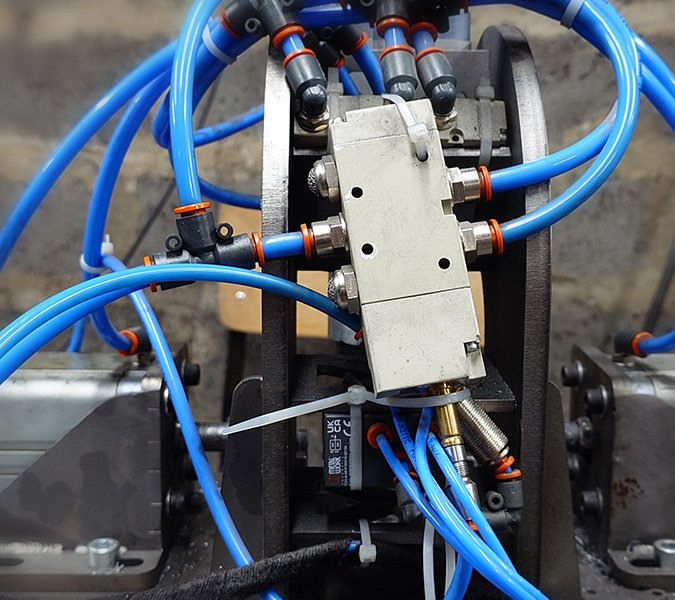

Machining on dedicated workstations

This is mechanical processing performed on machines and equipment specially designed and built by us for specific castings. Their main purpose is to maximize efficiency, which leads to shorter delivery times in mass production.